Situation

Wide pressure range, pumps with different shaft diameters in unmanned pump stations

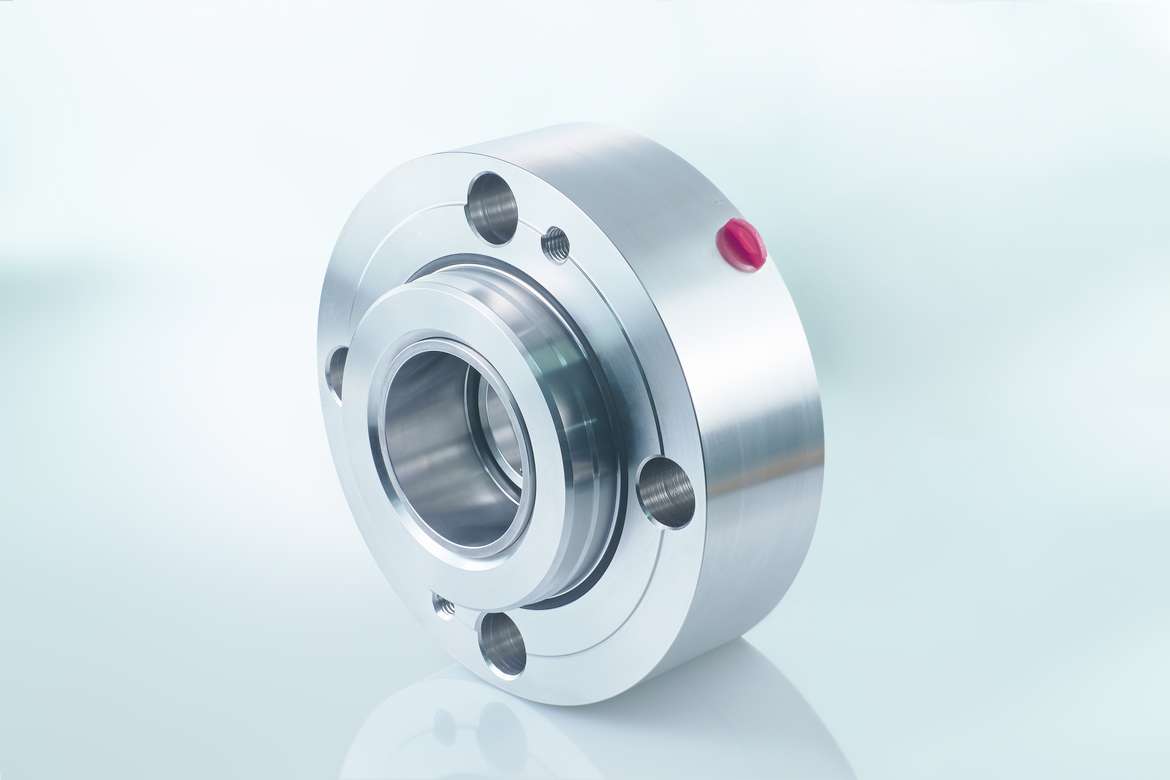

Mechanical seal SHVI and Plan 66A for unmanned pump station of an oil pipeline

Wide pressure range, pumps with different shaft diameters in unmanned pump stations

Requested was a single seal that is just as safe as a double seal with buffer pressure system

Mechanical seal SHVI from EagleBurgmann with optimized Plan 66A

A well-known Canadian operator of an oil pipeline commissioned EagleBurgmann to develop a sealing solution for crude oil pumps. The requirement: It needed to be a single seal that was just as safe as a double seal with buffer pressure system. In addition, the sealing solution was not to be designed for only one pump type but should be installed in various pumps of one station.

The operating parameters were quite extensive: The seal needed to be suitable for a pressure range from 2.5 bar (36 PSI) to 99 bar (1,436 PSI) as well as for shaft diameters from 115 mm to 155 mm (4.53'' to 6.10''). Since the pump stations are operated unmanned, the seal must operate without an additional supply system. To protect the environment and personnel, however, the seal housing must not leak if the seal fails unexpectedly.

These requirements were best met by the SHV series which has proven itself thousands of times over in crude oil pumps and MOL pumps (MOL: Main Oil Line) of all types worldwide for many years. For the Canadian customer, EagleBurgmann developed the SHVI sealing variant with loosely inserted seal face specifically for the high-pressure range. The seal face is designed such that it always builds a parallel sealing gap with the stationary seat. The deformation behavior of the seal face was optimized for use in crude oil pumps so that the seal operates reliably even under very high pressures, sliding velocities and temperatures as well as pressure and temperature fluctuations.

EagleBurgmann selected a special quality of the silicon carbide material to be used in the pumps of the pipeline operator. This provides the seal face with particularly good emergency running properties and tolerance for partial dry running. In addition, the sliding faces have extremely precisely ground grooves which allow the seal face to be lifted quickly even in the low pressure range and contribute to stable operation in a wide pressure range.

Plan 66A, which has been available since introduction of API 682 4th Edition, was the obvious choice for the safety concept. Accordingly, the seal housing contains two throttles, and the seal chamber is connected to a pressure transmitter.

EagleBurgmann optimized the plan and uses a special inner, floating throttle. This can withstand a product pressure of 99 bar (1,440 PSI) in an emergency. The pressure transmitter detects pressure changes in the seal chamber and signals an alarm if certain values are exceeded. At the same time, the seal leakage accumulated under low pressure is discharged to a central collection system in the pump station.

The SHVI seal and the optimized Plan 66A were subjected to dynamic and static tests individually and together on EagleBurgmann test benches. The constant and reliable sealing performance in all operating states and the safe function of Plan 66A in the event of a fault provided impressive results. The required system safety was provided at all times.

There are plans to convert further pumps of the pipeline operator. The new concept of the SHVI single seal with optimized Plan 66A is economical, modular, reliable in operation and offers the safety of a double seal. For other customers as well, this type of seal has since proven itself in MOL pumps for several thousand operating hours.

Do you have a similar requirement? Please contact us.

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.